We Are Factory

Beer Brewery Machine Manufacturer

We produce all equipment necessary for the production of beer. If you are looking for a reliable and efficient manufacturer of beer brewery machine then you have come to the right place. There is absolutely nothing to worry about when you chose us to manufacture your beer brewery machine because we will always give you the best. If you want to learn more about our beer brewery machine or how we operate, click on the get a quote button below to get started.

Fast And Easy to Operate

Our beer brewery machine will machine your production processes faster with more production yields. It is also easy to use and doesn’t require much expertise to operate.

Large Production Size

When you are looking for a reliable and safe CIP system that will serve the purpose of why you purchased it then getting our CIP systm will do the job for you. Our CIP system is safe to operate and maintain. It doesn’t break down at any slight mishandling.

Efficient and Reliable

Our machine stands out as one of the best Beer brewing machine in the industry. It is very durable and can stand heavy load. It’s very reliable and will serve you whenever you want to make use of it.

Brief Introduction of

Beer Brewery Machine

Beer brewery planning and design, beer brewing equipment and brewing technical support, brewery equipment operation and beer technical training, after-sales service including raw materials supply and equipment maintenance.

The beer manufacturing machine has a lot of features and benefits including

- Breweries – beer production lines that include the pre-defined set of equipment to production beer according to required production capacity.

- Malt processing equipment – devices needed to storage, transport and squeezing of malt grains immediately before beer brewing process.

- Wort brew equipment – devices and machines to production of wort before the beer fermentation process.

- Beer fermentation equipment – beer fermentation tanks and all devices needed for the beer primary and secondary fermentation process.

- Beer final conditioning equipment – Equipment for extraction of hops into beer, filtration, pasteurization, carbonization of beer and other conditioning operations with beer – the final beer processing.

Technical Features of Beer Brewery Machine

| Raw Material | Malt |

| Final Products | Beer |

| Processing Capacity | 100L-2000L/day |

| Package Options | kettle, bottles |

| No. | Equipment name |

| A | Mash/kettle tun, |

| B | Lauter/whirlpool tun |

| C | Fermentation tank |

| D | Bright beer |

| E | Filling machine |

| F | Chiller, boiler, air compressor |

Our Factory

Why Choose Us Be Your Beer Brewery Machine

Solution Provider

There are lots of things one has to consider before picking a manufacturer to manufacture a brewery machine. We have so many advantages over the rest and that is why choosing us to be your brewery machine provider will never be a mistake. You have made the right choice by coming to us.

- Our brewery installations are characterized by cost effectiveness, efficiency and resource-conserving operation.

- Our Nutrient film technique will help you produce excellent nutrient filled final products.

- Our systems offer you great flexibility in the brewing of different types of beer or the launching of new beers.

- We fulfill our demands on quality by means of meticulous construction and the use of high-quality components.

- We work with brewers large and small to design and fabricate custom brewhouses, cellar tanks and various other sophisticated brewery-specific support vessels and systems.

Our Certificates

On this site you can see our portfolio of the predefined configurations of breweries, machines, devices and systems designed for production beer. We have an abundance of expertise and strict quality measurement system, our beer manufacturing machines have gained professional certifications from both home and abroad.

Customize Your Own Beer Brewery Machine and Get More Details

How is the Beer Brewery Machine manufactured?

Raw Material Inspection

This is the first stage of our manufacturing process, we will inspect the raw materials to make sure that the materials are industry standard.

Preparation Procedure

After the raw material inspection, we will now map out the preparation procedure.

Laser Cutting

At this stage we will go into laser cutting of all the heavy materials and other materials that needs cutting.

Mechanical Work

After the cutting of the tools comes the mechanical work.

Welding

We will at this stage weld all the metals and joints that need to be welded.

Welding Inspection

We will at this stage inspect all the welded parts to makes sure that they are done correctly.

Polishing

All the materials that need to be polished will now be polished at this stage to give it crispy shiny look.

Assembling

This is where we begin the assembling process of the different parts of the machines.

Packing and loading

At this stage, we would have finished the manufacturing and your machine will be getting ready to be shipped and delivered.

Shipping

This is the last stage of our working process, we will ship your machine at this stage after the production has been completed.

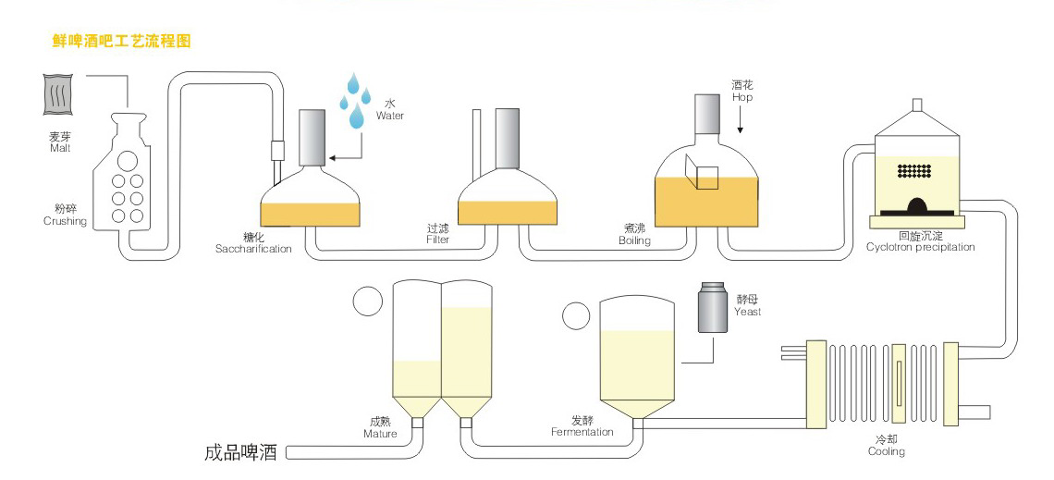

Flowchart of The Beer Brewery Machine

01.

Inquiry

First things first, you need to make enquiry to know how we work

02.

Quotation

We will then give you our quotations and how we work

03.

Factory Inspection

You can come to our factory to see things for yourself. You need to see that we are capable of giving you what you want

04.

Contract

When you are done with the factory inspection process, then we can now go into contract with you to manufacture what you want.

05.

Project team

This is where we will select the team that will be in charge of the project. We will select the best team we have to handle your project.

06.

Design drawing

Our Engineers will at this stage produce a prototype of the machines that we will manufacture for you and if it pleases you, we will continue with the process.

07.

Purchase

At this stage, you will have to make payment for the manufacturing process to begin properly.

08.

Manufacture

This stage is where we begin to manufacture your machines according to the requirements and consensus we have reached.

09.

Goods inspection

After the manufacturing has been completed, you will have to come and make the final inspection before we can make the delivery to your factory.

10.

Delivery

This stage involves delivering the manufactured machines to your own factory for installations.

11.

Installation

Our engineers will then come and install the machines in your factory and ensure that it is working effectively before you can start use.

12.

After-sales service

We will do a follow up after you have started using your machines and if there are any challenges, we will be there to assist you resolve them.

FAQ

Beer is almost as old as human civilization and, alongside bread, is one of the single most defining foods in history. Without beer, humans would have taken longer to settle into agriculture, and perhaps even the discovery of the American continent would look entirely different. Beer is an irreplaceable part of the human journey, and it would be difficult to imagine history without it.

While the beer recipes and beer brewing equipment of today look nothing like their predecessors, it’s clear that this advancement benefits everyone including the brewery owners, workers, and beer consumers alike. The beer industry is only going to continue expanding in the upcoming years, without any signs of stopping.

Beer is an alcoholic beverage obtained from the brewing and fermentation of cereals. It is said to have many health benefits when consumed in moderate amounts. The manipulation of yeasts strains and modifications in the brewing process has given rise to distinct beer types. This review gives a clearer picture on the art of beer production, its fermentation and various health benefits associated with beers.

The future of beer brewing lies in even more automation, sophisticated tools that allow brewers to fine-tune their brewing processes to perfection, and hopefully even more experimentation and boldness in coming up with a craft brew that will blow everyone away.

The journey of making beer is made up of five basic steps:

- Malting: The process of brewing begins with the grins by far the most common being barley. This barley is first harvested then malted. This is a process where the grains are allowed to sprout or germinate. The barley is heated to stop the sprouting at the optimal time. Then it is further dried under varying heat. Malting isolates the enzymes that are required for brewing. The temperature and length of time it is heated alters the character the malt will bring to the beer. Some malt are even roasted or toasted to bring out unique flavour and color. These are known as specialty malts.

- Mashing: The next step is mashing. The malted barley is cracked through a grain mill. Then it is stepped in hot water. This mixture is called Wort. As long as you know how to make tea, you will be able to do this without any major disasters. Both processes are very similar. This helps to activate the enzymes in the barley so that they start breaking down and releasing the sugars.

- Boiling: The Wort is now boiled and at the same time hops are added at several points. Hops are responsible for adding distinctive flavors to the beer. They also act as natural preservatives. The variety of the hop and how long it is in the boiled controls how its flavour and aroma will contribute to the beer.

- Fermentation: After boiling, the Wort is cooled and removed from the grains. Beer yeast is added to the Wort. The brewing process is now over and it is time for microbes to play their part. For a period of about 5 days, the beer yeast will consume the natural sugars in the Wort and metabolize them into both alcohol and carbon dioxide.

- Bottling and aging: Once the beer is fermented, it will be mostly flat or un-carbonated. At this point, the beer is either bottled or kegged and CO2 is forced into it. While many home brewers keg their beer and force-carbonate it, most still bottle. They add a small, specific amount of sugar just before bottling the beer. This facilitates a small fermentation under pressure which creates the carbonization the beer needs.

In the modern age, during milling, the crush of the grain can be changed remotely. Mashing is more precise, and its temperature can easily be changed at each step of the process. Laboratory science offers new ways of adding hop and packaging processes that save both time and money for brewers of any size. The real game-changers in the beer industry are conveyor systems. An automated system for moving grain and other brewing materials increases productivity and profit, but it also provides workplace safety. Conveyors reduce the amount of physical labour and heavy machinery operating the workers have to carry out each day. At the same time, worker morale and general well-being don’t suffer.

Beer has many health benefits if it is consumed in moderate amounts. Some of these interesting health benefits would include the following:

- Anti-cancer properties

Hops used in beer, through its flavonoid compound called xanthohumol plays a major role in the Chemoprevention of cancer, including prostate cancer.

- Reduced risk of cardiovascular diseases

Beer contains Vitamin B6 which against heart disease by preventing the build-up of a compound called homocysteine. Moderate beer consumption increases bone density, thereby preventing the risk of fractures and osteoporosis.

- Diabetes

Moderate beer consumption would have a lower prevalence of type 2 diabetes.

- Prevention of Anaemia

Beer is a good source of Vitamin B12 and folic acid which present Anaemia. Vitamin B12 is also essential for maintaining normal growth, good memory and concentration.

- Hypertension

Regular beer drinkers would have lower blood pressure, compared to people that consume similar amount of wine or other spirits.

- Anti-aging properties

Bee increases the potency and impact of Vitamin E, which is a major antioxidant in the body. It is an important part of the healthy skin, while also slowing down the aging process.

Below are the benefits of beer brewing machine:

- Equipment simple, invest small

- Pipeline simple, the operation easily

- The equipment height is low; the height requirement for the site is not high.

- Only can use extraction and filtering during the work filter (the wort in the lauter tun, can extract the wort by the work pump, and then pump in the kettle/whirlpool tank). The filter speed is relatively slow, no too higher requirement for brewers. Once the operation is wrong, the wheat layer is tight and the filtration is difficult. The heavy results will cause the sieve plate to deform and affect the subsequent use.

- In general, the beer equipment manufacturing industry will set up agitator in the kettle/boiling tank, because the kettle/boiling tank has functioned with whirlpool, the agitator will affect the effect of the whirlpool.

- The water for washing grain need to prepare in advance, store in the tank or fermenters (usually does not recommend a store in the fermenters, if operate wrong, easy to form a vacuum in the fermentation tank or affect the operation of ice water system), operation trouble, high heat loss.

- In order to reduce the influence of whirlpool, this type of equipment usually will not be equipped with the anti-rotation cross, it was mainly installed in the mashing tank. The function is to prevent vortex from when pouring down the wort. Obviously, there is no mashing/boiling pot with the anti-rotation cross. When it pours, it will be easy to form a vortex, which will cause gas to enter the wort pump, which will form an air binding on the wort pump. It will cause a large amount of gas to enter the wort pump, forming cavitation, affecting the life of the wort pump.

- When mashing, only the mashing with add wort method can be used, the mashing temperature step is less, and the quality of the malt is higher.

- Generally, only two batches can be brewed per day, and the craft brewers need to work overtime.

Below are the major ways to maintain beer brewing machine:

- Cleaning refers to soil, dirt and visible stains being removed. This is the same level as washing crockery and cutlery. Everything you use during a brew should be spotlessly clean and free of dust or grease. Mind when cleaning plastic items that you avoid using hard scouring pads or anything that might scratch the surface, as those little scratches are an ideal place for microbes to hide.

- Sanitising is the next step up and means reducing any potential sources of microbial spoilage to irrelevant levels. That is, you are getting rid of what you can’t see to minimise the chances of anything spoiling your lovely drink. This is an integral part of brewing. This isn’t very difficult at brew, just clean your equipment after it has been used and you can be confident that the sanitising just before the next use will be effective.

- There is a third stage, sterilising, which is the elimination of all forms of life on the object. Unless your brewing set up is in a hospital clean room and you are wearing fully sealed gear, the space you brew in won’t be sterile. Given that, sanitising your equipment is the best way to ensure that even at the microbial level there shouldn’t be enough to cause any infections.

Contact Us to Get Your Solution

Need some more information about our fruit processing machines and how to get yours? Get in touch with us by filling out the form provided below.